Understanding Timken Bearings

Timken bearings are a pivotal category within the realm of mechanical components, specifically designed to manage both axial and radial loads effectively. These bearings are characterized by their tapered rollers, strategically positioned between an inner and outer ring. The architecture of these bearings allows for the accommodation of significant load capacities in both directions, making them a versatile choice for various industrial applications.

Design and Features

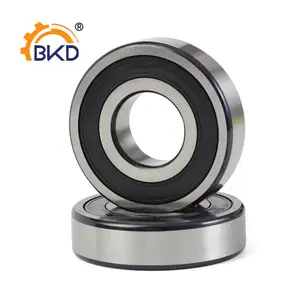

The design of tapered roller bearings is ingeniously crafted, with rollers that exhibit dual end diameters of varying sizes. A retainer maintains the necessary separation between these rollers, ensuring a consistent distance. This unique configuration is conducive to minimizing friction-generated heat, enhancing the bearing's operational lifespan. The assembly of these bearings is flexible, allowing the inner ring and cage to be mounted separately from the outer ring.

Size and Measurement Systems

Selecting the appropriate size of Timken bearings is a precise process, guided by a tapered roller bearing size chart. This chart is available in both metric (mm) and imperial (inches) units to cater to a global audience, ensuring that specifications meet the diverse requirements of various machinery and applications.

Load Capacity and Speed

When it comes to handling higher capacity loads, sealed tapered roller bearings exhibit a remarkable proficiency as compared to their ball bearing counterparts. Although ball bearings may surpass tapered roller bearings in terms of speed capabilities, they tend to generate more heat when operating at elevated speeds. Tapered roller bearings, however, are adept at managing large axial and radial forces concurrently.

Applications and Variations

The application of Timken bearings spans across numerous industries, from automotive to heavy machinery, due to their robustness and reliability. The product range includes various sizes and configurations, from tapered roller bearing housing to complete tapered roller bearing assemblies, ensuring a match for specific application needs without the constraints of a one-size-fits-all approach.

Material and Advantages

Crafted from durable materials, these bearings are built to last. The material selection is critical to the bearing's performance, offering resistance to wear and tear while maintaining structural integrity under stress. The advantages of utilizing Timken bearings are evident in their design efficiency, load endurance, and the ability to reduce friction, which collectively contribute to the longevity and reliability of the machinery they are a part of.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4