Popular in your industry

Related Searches:

Top categories

About monolithic mold

Understanding Monolithic Molds

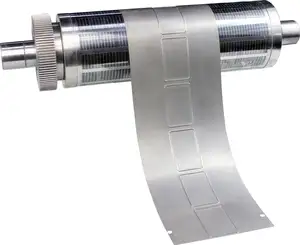

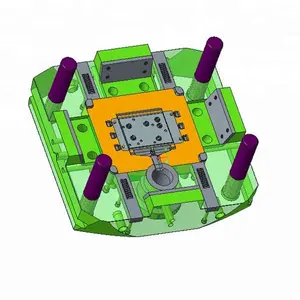

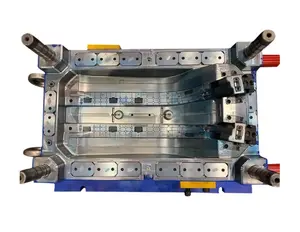

Monolithic molds are integral components in the manufacturing sector, designed for creating a myriad of products through a single, solid casting. This category encompasses a variety of molds used for different purposes, from intricate injection molds for small, complex items to larger designs such as bolection molds, which add ornamental value to door panels.

Types and Applications of Monolithic Molds

These molds come in diverse forms, each suited to specific applications. For instance, injection monolithic molds are pivotal in producing high-volume parts with precision, whereas larger monolithic structures are often sought after for their aesthetic contributions to architectural elements. The versatility of monolithic molds means they are indispensable in industries ranging from automotive to home decor.

Material Selection for Monolithic Molds

Selecting the appropriate material for a monolithic mold is crucial. Options vary from robust iron to innovative composites, each offering distinct advantages. The choice of material affects the mold's durability, the finish of the produced items, and the overall efficiency of the manufacturing process. Buyers can explore a range of materials to find the one that aligns with their production requirements.

Features and Advantages of Monolithic Molds

Monolithic molds are renowned for their robustness and ability to produce uniform products. They offer the advantage of repeatability, which is essential for mass production. Moreover, the potential to standardize certain elements of the mold, such as lift bars, connection sizes, and clamp slots, streamlines the manufacturing process, enhancing compatibility across various production setups.

Optimizing Production with Monolithic Molds

Investing in a monolithic mold can lead to significant cost efficiencies over time. By standardizing components of the mold, businesses can reduce the time and resources spent on adjusting molds for different products. This optimization can lead to a more streamlined production line, allowing for quicker turnaround times and increased output.

Choosing the Right Monolithic Mold on Alibaba.com

Alibaba.com serves as a gateway to connect with seasoned suppliers of monolithic molds. The platform facilitates the selection process, enabling buyers to specify their design and material preferences, and engage with suppliers who can provide molds tailored to their production needs. With a focus on customer satisfaction, suppliers ensure that the molds meet the exacting standards required for the buyers' specific manufacturing processes.