Popular in your industry

Related Searches:

Top categories

About masala packing machine

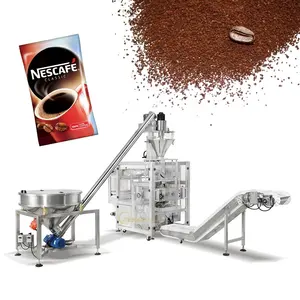

Introduction to Masala Packing Machine

A masala packing machine is a specialized piece of equipment designed for efficiently packaging various spices and masala mixes into pouches or containers. These machines are widely used in the food industry to automate the packaging process, ensuring accuracy, speed, and consistency in packing different types of masalas.

Technical Specifications of Masala Packing Machines

When looking for a masala packing machine, it's essential to consider various technical specifications to meet your packaging needs. These machines typically offer features like adjustable packing speed, pouch length adjustment, date printing, and multi-weight packaging options. Additionally, they come with different filling systems such as volumetric fillers, auger fillers, or combination weighers to suit different types of masala products.

Types of Masala Packing Machines

There are several types of masala packing machines available in the market, each designed for specific packaging requirements. Vertical form fill seal (VFFS) machines are popular for packing granular masalas, while rotary pouch packing machines are ideal for packing powders. Additionally, multi-head weighers are commonly used for accurate weighing and packing of masala mixes.

Advantages of Using Masala Packing Machines

Investing in a masala packing machine offers numerous advantages to businesses in the food industry. These machines help improve efficiency by automating the packaging process, reducing labor costs, and minimizing packaging errors. They also ensure hygienic packing, extend the shelf life of masala products, and enhance the overall productivity of the packaging line.

Choosing the Right Masala Packing Machine

When selecting a masala packing machine for your business, consider factors such as the type of masala products you are packing, desired packing speed, packaging material, and space availability. It's crucial to choose a machine from a reputable supplier that offers reliable after-sales support, spare parts availability, and customization options to meet your specific packaging requirements.

Features of Masala Packing Machines

Modern masala packing machines come equipped with advanced features to streamline the packaging process. These may include touchscreen interfaces for easy operation, self-diagnostic systems for troubleshooting, and servo motors for precise control over the packing process. Some machines also offer options for nitrogen flushing to extend the shelf life of packed masalas.

Use Scenarios for Masala Packing Machines

Masala packing machines find applications in a variety of settings, including spice manufacturing units, food processing plants, packaging facilities, and spice distribution businesses. Whether you are packing ground spices, whole spices, or specialized masala blends, these machines can cater to different packaging requirements with speed and accuracy.

Maintenance of Masala Packing Machines

To ensure the optimal performance of your masala packing machine, regular maintenance is essential. This includes cleaning the machine after each production run, lubricating moving parts, inspecting and replacing worn-out components, and calibrating the machine for accurate packing. Proper maintenance not only extends the machine's lifespan but also ensures consistent packing quality.

Cost Considerations for Masala Packing Machines

When budgeting for a masala packing machine, it's important to factor in not just the initial purchase cost but also ongoing operational expenses. Consider the cost of consumables such as packaging material, maintenance costs, energy consumption, and labor requirements. Additionally, weigh the benefits of investing in a high-speed, automated machine versus a manual or semi-automatic model based on your production volume.

Future Trends in Masala Packing Technology

As technology continues to advance, the future of masala packing machines looks promising with innovations focused on enhancing efficiency, reducing waste, and improving sustainability. Trends such as smart packaging solutions, eco-friendly materials, and IoT integration for remote monitoring and predictive maintenance are likely to shape the evolution of masala packaging technology in the coming years.