Popular in your industry

Related Searches:

Top categories

About liner bore machine

Introduction to Liner Bore Machines

Liner bore machines are essential equipment in the field of drilling and excavation. Designed to create precise boreholes in various geological settings, these machines are pivotal for water well drilling, geological explorations, and mining operations. Their versatility allows them to operate on different terrains, whether it's the ruggedness where caterpillar treads are necessary or areas accessible by rubber-tired vehicles.

Types and Applications

The range of liner bore machines encompasses models suitable for diverse drilling demands. From compact rigs that are perfect for small-scale projects like farm irrigation and residential water wells to robust machinery capable of reaching depths beyond 200 meters for commercial mining and exploration. The adaptability of these machines means they can execute vertical, horizontal, or angled drilling to suit the specific requirements of a project.

Technical Features and Specifications

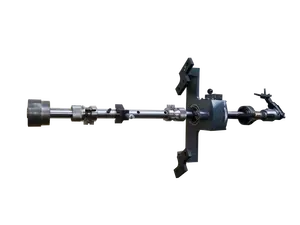

A liner bore machine is equipped with various technical features that enhance its drilling capabilities. The propulsion system, which may include caterpillar treads, allows for maneuvering inclines up to 25 degrees. Drilling speed and efficiency are contingent on the machine's power and the surface hardness, with hole diameters ranging from 90mm to 200mm. These machines often come with additional equipment such as air compressors, mud pumps, drilling rods, connectors, and a drilling tower, all integral to the drilling process.

Drilling Components and Methods

The core of drilling operations lies in the selection of appropriate drill bits. Choices include diamond bits, alloy ring-shaped bits, 3-wing alloy bits, PDC bits, and hammer bits, each catering to different drilling methods like rotary, percussion, blast hole, and core drilling. The composition and shape of the drill bit are critical factors that determine the efficiency and suitability for the material being drilled.

Advantages and Suitability

The advantages of using a liner bore machine are manifold. Smaller units offer the convenience of portability and are ideal for locations with limited access, making them suitable for domestic and agricultural use. Larger, more powerful machines provide the speed and force required for extensive commercial drilling operations. The selection of a liner bore machine should be based on the scope of work, with a focus on the machine's lifting power, weight, and the nature of the terrain.

Choosing the Right Liner Bore Machine

Selecting the right liner bore machine is crucial for achieving optimal drilling results. Prospective buyers should consider the depth of drilling required, the type of terrain, and the specific geological conditions they will be working with. While browsing the extensive range of liner bore machines, it's important to evaluate the specifications and features that align with the intended drilling objectives.