Popular in your industry

Top categories

About granite face polisher

Introduction to Granite Surface Finishing

Granite, with its aesthetic appeal and durability, is a popular choice for various construction and design projects. A crucial step in its application is the finishing process, which often involves a granite face polisher. This equipment is essential for achieving the smooth, reflective surface that granite is known for.

Types of Granite Face Polishers

The market offers a diverse range of granite face polishers, each designed to meet specific needs. From handheld devices for small-scale projects to industrial-sized machines for larger operations, the selection caters to a broad spectrum of requirements. Understanding the different types, such as single-head polishers or multi-head line machines, allows for informed decision-making.

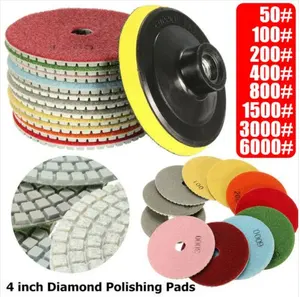

Features of Granite Face Polishers

When exploring the features of a granite polishing machine, precision and efficiency are at the forefront. These machines are engineered to handle the hardness of granite, with features that may include adjustable speed settings, water-cooling mechanisms, and diamond-infused polishing pads. The design of these polishers ensures minimal dust generation and uniformity in polish.

Applications and Advantages

The application of a granite polisher extends beyond just aesthetic enhancement. It's also about protecting the stone and extending its life. The advantages of using a dedicated polisher include improved resistance to wear and tear, and the ability to bring out the natural color of the granite. These machines are indispensable for creating countertops, flooring, and other granite surfaces.

Materials and Technology

Modern granite polishing tools are a blend of advanced technology and durable materials. The use of industrial-grade diamonds in the polishing heads is a testament to the robustness required to smooth granite surfaces. Additionally, the integration of computer controls in some polishers allows for precise and consistent results across large volumes of stone.

Selecting the Right Granite Face Polisher

Choosing the right granite surface polishing machine involves considering the material's hardness, the desired finish, and the production capacity. While Alibaba.com facilitates the connection between buyers and a vast array of suppliers, it is crucial to compare the specifications and features of different polishers to find the one that aligns with the project's needs.