Popular in your industry

Related Searches:

Top categories

About fuji smt pick and place machine

Introduction to Fuji SMT Pick and Place Machine

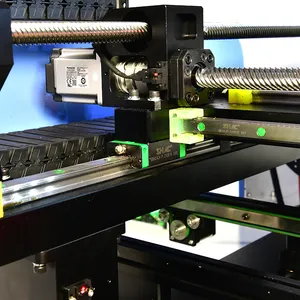

The Fuji SMT pick and place machine is a cutting-edge piece of equipment used in the electronics manufacturing industry for automated component placement onto printed circuit boards (PCBs). This advanced machine offers precision, speed, and versatility, making it an essential tool for high-volume production lines.

Technical Specifications

The Fuji SMT pick and place machine boasts a myriad of impressive technical specifications. It features high-speed placement capability, with placement rates reaching up to 60,000 components per hour. Additionally, the machine supports a wide range of component sizes, from 01005 chips to large connectors, ensuring versatility in production.

Features of Fuji SMT Pick and Place Machine

One of the standout features of the Fuji SMT pick and place machine is its advanced vision system, which enables precise component alignment and placement. Furthermore, the machine is equipped with intelligent software that optimizes production efficiency and minimizes errors, enhancing overall productivity.

Advantages of Using Fuji SMT Pick and Place Machine

Investing in a Fuji SMT pick and place machine offers numerous advantages to electronics manufacturers. Firstly, the machine streamlines the assembly process, reducing manual labor and increasing production output. Moreover, its high accuracy ensures consistent quality in PCB assembly, leading to fewer defects and reworks.

Choosing the Right Fuji SMT Pick and Place Machine

When selecting a Fuji SMT pick and place machine for your manufacturing needs, consider factors such as production volume, component diversity, and budget constraints. It's essential to choose a machine that aligns with your specific requirements to maximize efficiency and ROI.

Use Scenarios for Fuji SMT Pick and Place Machine

The Fuji SMT pick and place machine is ideal for a wide range of applications, including consumer electronics, automotive, aerospace, and telecommunications industries. Its adaptability to various component types and sizes makes it a versatile solution for diverse manufacturing environments.

Maintenance of Fuji SMT Pick and Place Machine

Proper maintenance is crucial to ensure the longevity and optimal performance of your Fuji SMT pick and place machine. Regular cleaning, calibration, and inspection of critical components such as nozzles and feeders are essential to prevent downtime and maintain production efficiency.

NXT Pick and Place Machine as an Alternative

For businesses seeking alternatives to the Fuji SMT pick and place machine, the NXT pick and place machine offers similar advanced features and performance capabilities. Both machines are renowned for their speed, accuracy, and reliability in PCB assembly processes.

Exploring Fuji Pick and Place Machines

Within the realm of pick and place machines, Fuji has established itself as a leading manufacturer known for innovation and quality. Fuji pick and place machines, including the Fuji SMT pick and place machine, are synonymous with precision engineering and cutting-edge technology.

Conclusion

In conclusion, the Fuji SMT pick and place machine represents a pinnacle of technological advancement in the electronics manufacturing industry. Its unparalleled speed, accuracy, and efficiency make it a must-have tool for businesses aiming to optimize their production processes and deliver high-quality electronic products.