Popular in your industry

Top categories

About custom bullet molds

Introduction to Custom Bullet Molds

Custom bullet molds are specialized tools used in the manufacturing of ammunition. These molds are designed to cast bullets to specific dimensions and weights, allowing for precision in shooting sports, hunting, and ballistic testing. The process of creating these molds involves detailed engineering to ensure that each bullet cast meets the required specifications for performance and safety.

Types and Applications

There are various types of custom bullet molds catering to different calibers and bullet shapes. From simple two-piece molds for hobbyists to complex multi-cavity molds for commercial production, the variety is extensive. These molds are used in a range of applications, including but not limited to, competitive shooting, law enforcement training, and personal defense ammunition production.

Material Selection for Molds

The material of a bullet mold significantly affects its durability and performance. Options include aluminum, iron, and steel, each offering distinct advantages. Aluminum molds heat up and cool down quickly, making them suitable for hobbyists, while iron and steel molds retain heat longer, providing consistency in mass production.

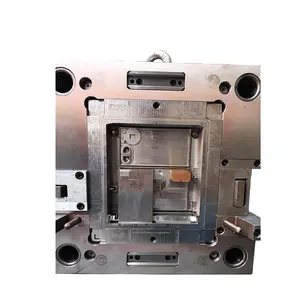

Features and Advantages

A key feature of custom bullet molds is the ability to tailor them to specific requirements. This customization can lead to better bullet uniformity and improved accuracy. Additionally, the use of standardized components in molds, such as lift bars and clamp slots, can enhance the efficiency of the production process and reduce overall costs.

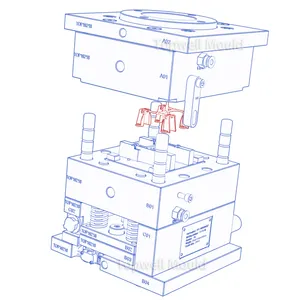

Design and Precision

The design process of custom bullet molds is intricate, often involving the creation of prototypes to ensure the final product meets the precise measurements needed for the bullet's intended use. This attention to detail ensures that the bullets produced will have the desired balance and aerodynamic properties.

Choosing the Right Mold

Selecting the right custom bullet molds involves considering the type of bullet, the material of the mold, and the production method. It is essential to collaborate with experienced manufacturers who can provide guidance and ensure that the mold is crafted to exact specifications.