Popular in your industry

Related Searches:

Top categories

About casting czech

The Czech Republic, with its rich industrial heritage, has emerged as a powerhouse in the global casting market, particularly in the realm of aluminum die-casting. This growth is fueled by the burgeoning automotive industry's demand for lightweight components and the rising production of household appliances. As Czech casting products gain prominence on international B2B platforms like Alibaba.com, it becomes essential for global traders to understand the nuances of this market. From specialized techniques in fly fishing to the advanced metalworking capabilities, the Czech casting industry offers a plethora of products characterized by precision, versatility, and innovation. This guide delves into the Czech casting landscape, exploring the diverse techniques, applications, and materials that define this vibrant sector.

The Emergence of Czech Casting Products on Global Platforms

The Czech Republic has become a notable player in the aluminum die-casting market, with its presence increasingly felt on global platforms such as Alibaba.com. The country's market has seen a steady growth trajectory, attributed to the rising demand for lightweight components, particularly from the automotive sector. This demand is complemented by the production of household appliances, which has been bolstered by an increase in disposable incomes. A significant shift towards the miniaturization of components has also played a crucial role in market expansion. Technological advancements, especially in high-pressure die-casting (HPDC), have further propelled the Czech market to new heights, making its products a mainstay on international B2B platforms. These developments reflect the Czech industry's commitment to innovation and its ability to adapt to the evolving needs of various industries.

Understanding the Diversity of Czech Casting Techniques

The specialized technique within the fly fishing community, is characterized by its unique casting style. The method involves short, precise casts, typically no longer than the rod itself, allowing the angler to maintain control and keep the lures just below the rod's tip. The effectiveness of this technique is enhanced with a longer rod, designed for light lines. These longer, lighter rods offer increased sensitivity, crucial for detecting subtle takes. The approach requires the angler to cast upstream and then hold the rod high, positioning the tip just downstream of where the line enters the water. This facilitates a controlled drift, keeping the line tight and in constant contact with the lures as they move with the current. The immediacy of the connection between the angler and the fish is often described as electric, with strikes being directly transmitted through the tight line, offering a more immediate and intimate fishing experience.

Types of Czech Casting Products Available on Alibaba.com

Alibaba brands are recognized for their extensive expertise in the field of metalworking, particularly in the production of aluminium die castings and die forgings from non-ferrous metals. The advanced machinery and commitment to technological investment contribute to the precision of their manufacturing processes, enabling them to fulfill the intricate requirements of a diverse clientele. Their product range is comprehensive, catering to various sectors and is utilized by notable international companies, indicating a strong demand for their castings and forgings in the global market.

The products are integrated into a multitude of applications, including the automotive and electrical industries, showcasing the trust and reliance placed on Czech casting products by leading manufacturers. This highlights the versatility and reliability of the casting products that originate from the Czech Republic and are available for global traders on platforms like Alibaba.com.

Applications of Czech Castings in Various Industries

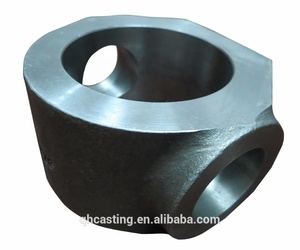

Czech castings have found their applications across a multitude of industries due to their versatility and adaptability. The expertise in producing intricate castings from gray and ductile iron caters to the engineering demands both within the Czech Republic and internationally. These castings are integral to the manufacturing of a wide array of components such as machine stands, beds of machining tools, tables, foundation plates, clamping plates, press frames, gearbox housings, flywheels, gears, chain wheels, pulleys, valves, smoothing spindles, elbows, and counterweights. The manual molding into frames and earth (casings) using furan resin-based molding mixtures, followed by thermal treatments like annealing to relieve stress, exemplifies the specialized techniques employed. This process ensures that the castings meet the rigorous requirements of various sectors, highlighting the Czech industry's commitment to delivering solutions that support the functionality and efficiency of complex machinery.

Key Features and Advantages of Czech Casting Products

Czech casting techniques have evolved to create components that are integral to a variety of applications, showcasing a blend of precision and versatility. The casting processes employed include investment casting, also known as lost wax casting, which allows for the creation of parts with intricate details and complex shapes. This method is complemented by the use of durable materials like stainless steel, aluminum, and brass, which contribute to the longevity and reliability of the cast products.

Additionally, the adaptability of Czech casting is evident in the production of custom parts through methods like sand casting and die-casting. These techniques are capable of handling various metal alloys, ensuring that each component meets specific industry standards and application requirements. The resistance to corrosion and the ability to withstand high temperatures make these castings suitable for demanding environments.

The Czech casting industry's commitment to precision is also seen in the production of high-precision parts for automotive, aerospace, and industrial machinery. The use of advanced technologies in the casting process ensures that each piece meets stringent quality control measures, resulting in parts that are not only robust but also have a high degree of dimensional accuracy, which is critical for complex assemblies.

Material Selection in Czech Casting: Ensuring Quality and Durability

The material selection for Czech casting is a critical factor that contributes to the quality and durability of the final products. Manufacturers utilize a variety of metals and alloys to cater to the diverse needs of different industries. For instance, the use of stainless steel, such as 304-grade, is prevalent in creating parts like large diameter flanges due to its resistance to corrosion and its strength. Aluminum alloys are favored in high-pressure die casting for their lightweight and durability, which is essential for mechanical accessories. The inclusion of materials like gray iron and ductile iron in casting offers excellent wear resistance, which is crucial for parts like gearboxes and compressors.

In addition to traditional metals, advanced materials such as bronze and brass are also employed in the casting process to achieve specific properties. For example, bronze is often used for its excellent resistance to seawater corrosion, making it suitable for marine applications. The adaptability of Czech casting is further enhanced by the use of zinc, titanium, and aluminum in low-pressure die casting, which allows for the creation of small, intricate parts with high precision. The versatility of material options ensures that buyers can find the most appropriate Czech casting products to meet their specific application requirements.

Navigating for the Best Czech Casting Suppliers

Navigating for Czech casting suppliers presents a variety of options to cater to diverse casting needs. The assortment includes a range of Czech casting techniques and materials, reflecting the industry's innovation and adaptability. Suppliers are vetted to ensure they meet stringent quality and safety standards, providing peace of mind for buyers looking for reliable casting solutions. The offerings span different sizes and designs, showcasing the flexibility to serve specific requirements across various industries.

The Czech casting products are produced with a focus on durability and performance, utilizing materials that are resistant to corrosion and wear. This emphasis on material quality underscores the longevity and cost-effectiveness of the products. For businesses seeking to optimize their casting operations, the user-friendly interface and detailed supplier listings make it easier to compare and select the most suitable products. The diversity of available castings ensures that whether for specialized or general applications, the needs of buyers are met with precision.

Conclusion

The Czech casting industry stands as a testament to the synergy between traditional craftsmanship and modern technology. Suppliers offer a wide array of casting products, from intricate fly fishing components to robust automotive parts. The industry's evolution is marked by the adoption of diverse casting techniques and the strategic selection of materials, ensuring high-quality, durable products. The adaptability to create custom parts for various industries underscores the Czech casting products' reliability and precision. For global traders, navigating the offerings reveals a commitment to excellence, with suppliers meeting rigorous quality standards. In conclusion, the Czech casting sector is a vital contributor to the global market, providing solutions that enhance the functionality and efficiency of machinery across industries. Its continued growth and innovation position it as a key player for traders seeking superior casting products.