Popular in your industry

Top categories

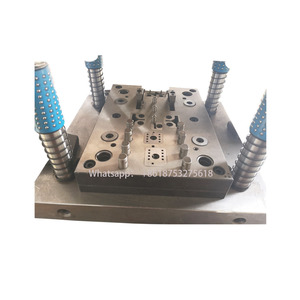

About cad weld mould

Introduction to CAD Weld Moulds

CAD weld moulds are specialized tools used in various industries to create precise and durable connections through a process known as exothermic welding. These moulds are designed to ensure a consistent and high-quality weld that is crucial for establishing strong metallic bonds, particularly in electrical grounding and bonding applications.

Types and Applications

There are several types of cadweld moulds tailored to different welding requirements. From simple cable connections to intricate grounding systems, these moulds cater to a broad spectrum of applications. Industries ranging from telecommunications to construction utilize cad weld moulds for their reliability and precision in creating permanent connections that are essential for safety and functionality.

Features and Materials

The features of a cad weld mould include its ability to withstand high temperatures and its adaptability to various welding situations. Materials commonly used in the construction of these moulds include graphite and high-grade ceramics, chosen for their heat resistance and durability. The design of a cadweld mould is critical, as it directly impacts the effectiveness of the weld.

Advantages of Using CAD Weld Moulds

Utilizing cad weld moulds in exothermic welding processes offers numerous advantages. These moulds provide consistent results, which is paramount for the integrity of electrical connections. The longevity and reusability of a quality cadweld mould also make it a cost-effective solution for many welding projects.

Selection Considerations

When selecting a cad weld mould, it is essential to consider the specific requirements of the project. Factors such as the type of metals being joined, the environmental conditions, and the expected load on the connection will influence the choice of mould. Suppliers on Alibaba.com offer a variety of moulds to meet these diverse needs, ensuring that buyers can find the appropriate tool for their welding tasks.

Optimizing Production with CAD Weld Moulds

Incorporating cad weld moulds into production can lead to increased efficiency. By standardizing certain elements of the mould, such as connection sizes and clamp slots, businesses can streamline their operations and reduce the time required for setup and welding. This standardization also facilitates the interchangeability of mould components, further enhancing productivity.