Introduction to Automatic Ring Making Machines

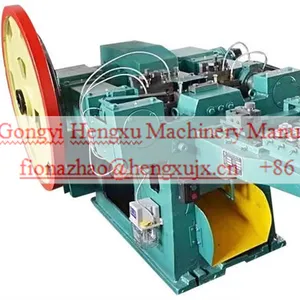

The realm of metal fabrication has been revolutionized by the advent of automatic ring making machines. These machines are pivotal in the production of rings used in various industries, ranging from construction to jewelry. The technology behind these machines allows for the mass production of rings with minimal manual intervention, ensuring consistency and efficiency in manufacturing processes.

Types and Applications

There is a spectrum of ring making machines catering to different market needs, including the fully automatic ring making machine and the semi automatic ring making machine. Each type serves distinct applications, from creating TMT bars in the construction industry—where machines like the automatic tmt bar ring making machine are essential—to forming delicate rings for the jewelry sector. The versatility of these machines means they are indispensable in settings such as building material shops, hotels, and advertising companies.

Features and Materials

Automatic ring making machines are designed to work with a variety of materials. Machines capable of handling metals like brass, copper, carbon steel, and alloys are common, allowing for a broad range of end products. Features of these machines often include high productivity levels and the ability to produce rings for various applications, including food, beverage, and chemical industries. The automatic ring bending machine is particularly noted for its precision in shaping rings to exact specifications.

Advantages of Automation in Ring Manufacturing

The transition to automation, with devices such as the ring banane ki automatic machine and the ring banane wali automatic machine, offers numerous advantages. These machines reduce the labor intensity traditionally associated with ring production, while also minimizing the potential for human error. The result is a more uniform product that can be produced at a faster rate than manual methods would allow.

Choosing the Right Machine

Selecting the appropriate automatic ring making machine depends on the specific requirements of the production process. Manufacturers and businesses must consider factors such as the type of material being used, the desired output rate, and the specific end use of the rings. For those in the construction sector, a fully automatic tmt ring making machine might be the preferred choice, while a general automatic ring forming machine could suffice for a variety of other applications.

Conclusion

In conclusion, the automatic ring making machine category encompasses a range of equipment designed to meet the diverse needs of modern manufacturing. From heavy-duty construction applications to delicate jewelry making, these machines provide a high level of precision and efficiency. While the market offers various models and features, the core value lies in their ability to enhance productivity and ensure consistency in product quality.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4