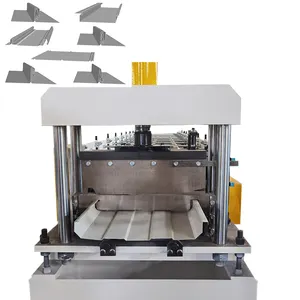

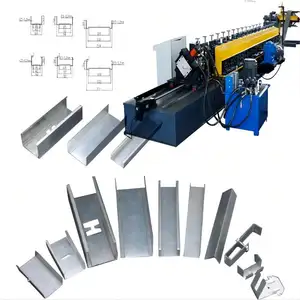

Introduction to Aluminum Standing Seam Forming Machines

Aluminum standing seam forming machines are specialized equipment designed for the production of metal roofing components. These machines craft long-lasting and aesthetically pleasing standing seam panels, which are a staple in modern roofing thanks to their durability and weather-resistant properties. The technology behind these machines allows for precise bending and cutting, ensuring each panel is consistent in quality and dimension.

Types and Applications

The versatility of aluminum standing seam forming machines extends to various applications, from residential to commercial roofing. These machines are capable of producing panels for roof pavements, wall cladding, and other architectural elements. The adaptability of the equipment allows it to handle different aluminum grades, catering to a range of structural requirements and design preferences.

Operational Features

Seam lock forming machines are engineered for ease of operation, with features that streamline the production process. They typically include programmable logic controllers (PLCs) for automated production, which enhances efficiency and reduces the likelihood of human error. The machinery's design focuses on user safety and ergonomic operation, ensuring a safer workplace and minimizing operator fatigue.

Material and Construction Advantages

Constructed to handle the rigors of industrial use, these machines are built with high-grade materials that resist wear and tear. The use of aluminum in the machine's own construction reduces its weight, making it easier to install and relocate within a manufacturing setting. The end product, aluminum standing seam panels, offers a lightweight yet robust solution for roofing, boasting a high strength-to-weight ratio.

Innovative Solutions in Tile Production

Beyond roofing, metal tile making machines expand their utility to the production of tiles for flooring and wall applications. Innovations in machine design allow for the creation of tiles that meet various aesthetic and functional demands, from ceramic-like finishes to rugged, slip-resistant surfaces suitable for outdoor use.

Meeting Diverse Construction Needs

For businesses aiming to cater to a broad spectrum of construction needs, aluminum roof panel machines offer a solution that can be tailored to different project specifications. Whether the requirement is for residential roofing or commercial projects, these machines provide the capability to produce a range of products without compromising on efficiency or quality.

Incorporating an aluminum standing seam forming machine into your production line could significantly enhance your operational capabilities. With a focus on delivering reliable and consistent output, these machines are a cornerstone for businesses looking to excel in the competitive market of construction materials.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4