Popular in your industry

Related Searches:

Top categories

About 65mm extruder machine

Introduction to 65mm Extruder Machines

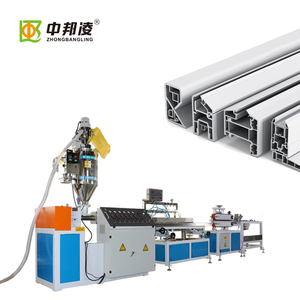

The 65mm extruder machine stands as a pivotal component in the plastic processing industry. This machinery is engineered to melt and reform plastic materials into a variety of products, ranging from pipes to sheets, leveraging the plastic extrusion process. Its specific diameter, 65mm, refers to the size of the screw used to push and mold the plastic, making it a versatile tool for medium-scale production demands.

Types and Applications

Extrusion machines, particularly those with a 65mm screw, are utilized across various sectors. These include the recycling industry, where they play a crucial role in repurposing plastic waste into new products. In the realm of construction, these machines are instrumental in fabricating plastic pipes, while the packaging sector relies on them for producing films and sheets. The plastic extrusion equipment is adaptable, catering to specialized applications such as laboratory experiments or niche manufacturing processes.

Features and Materials

A 65mm extruder machine is designed to handle a broad spectrum of plastic types, from polyethylene to PVC. The core components are crafted from robust materials capable of withstanding high temperatures and continuous operation. The machine's features include temperature control systems, variable speed drives, and die heads that can be swapped to create different product profiles. The intricacy of the machine's design allows for precise control over the extrusion process, ensuring consistent product quality.

Advantages of Using a 65mm Extruder

The advantages of employing a 65mm extruder machine are manifold. Its size is particularly suited for businesses that require a balance between output capacity and space economy. The dual-screw variant of this machine offers increased efficiency, as the twin screws work in tandem to double the production rate. Conversely, the single-screw model is valued for its simplicity and ease of maintenance, making it suitable for operations with lower throughput requirements.

Choosing the Right Machine

Selecting the appropriate extrusion machine involves assessing the material compatibility and the production capacity of the device. For businesses focused on pipe manufacturing, ensuring the machine can meet the required specifications is paramount. Similarly, for those in the packaging industry, a machine capable of producing high-quality films and sheets is essential. The choice between a single or double screw machine will largely depend on the desired efficiency and output rate of the production process.

Conclusion

The 65mm extruder machine is a critical investment for manufacturers looking to optimize their plastic production processes. Its ability to handle various materials and produce a wide range of products makes it a versatile and valuable piece of equipment. While exploring options on Alibaba.com, buyers can find a diverse selection of machines to meet their specific production needs without the constraints of brand affiliation or promotional bias.