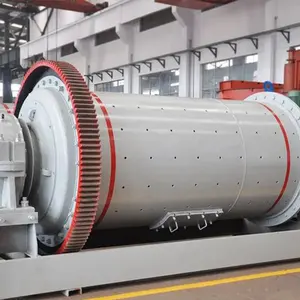

Understanding the 200 Mesh Ball Mill

The 200 mesh ball mill is a pivotal piece of equipment in the mining sector, designed to grind down ores and rocks for metal extraction. This category of milling machinery is tailored to produce particles that pass through a 200 mesh screen, ensuring the fine consistency needed for efficient mineral processing.

Types and Applications

Within the realm of grinding equipment, the ball mill for mineral processing stands out for its capability to handle a wide range of materials. The 200 mesh grind is particularly suited for operations involving gold, iron, and aluminum ores, where it facilitates an effective separation of metals from the ore.

Features and Efficiency

A 200 mesh ball mill is equipped with ball-type grinders that operate within chambers to achieve the desired fineness. The efficiency of these mills is notable, minimizing friction and reducing energy consumption during the grinding process. This efficiency is paramount in industries where volume and overheads impact profitability.

Materials and Advantages

Constructed to withstand the rigors of ore processing, the grinding mill is made from robust materials that ensure durability and longevity. The advantage of using a fine mesh ball mill lies in its ability to produce a consistent and uniform particle size, which is crucial for subsequent metal extraction processes.

Choosing the Right Mill

Selecting the appropriate ball mill for mining is critical. Factors such as ore type, volume, and desired final product size play a significant role. The 200 mesh ball mill is a versatile option that caters to a variety of needs, from small-scale operations to large-volume industrial mining.

Integration into Mining Operations

Incorporating a 200 mesh ball mill into mining operations can lead to more efficient metal extraction, yielding more metal per kilogram of ore processed. Its low energy consumption also helps in keeping operational costs at bay, making it a valuable addition to the mining machinery arsenal.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4