Popular in your industry

Related Searches:

Top categories

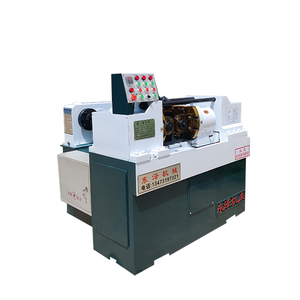

About nut bolt automatic machine

Introduction to Nut Bolt Automatic Machines

Exploring the realm of industrial machinery, nut bolt automatic machines stand out for their specialized role in the manufacturing sector. These machines are engineered to automate the production of nuts and bolts, which are essential components in various industries. The automation process not only enhances efficiency but also ensures consistency in quality, which is crucial for the integrity of the final products.

Types of Nut Bolt Automatic Machines

The diversity in automatic nut bolt manufacturing machines caters to different operational needs. Horizontal forging machines are designed for bar stock finishing and pre-forming, utilizing a crank gear system for their primary movements. In contrast, vertical forging machines, which move their tools vertically, are more suited for smaller forgings such as hooks and blanks for knives. Forging rolls, another variant, focus on increasing production efficiency during the forging process. Lastly, rotary forging machines, which are adept at hot drawing and swaging, operate with either rotating yokes or spindles, depending on the model.

Applications and Features

The application of automatic nut bolt machines spans across various industries, from automotive to construction, where precision and volume are paramount. These machines boast features such as high production rates and the ability to handle repetitive tasks with precision. The rotary forging machine, for instance, uses rotational movements to intricately shape metals, demonstrating the advanced capabilities of these machines.

Materials and Advantages

Constructed from robust materials, nut bolt automatic machines are built to withstand the rigors of industrial environments. The durability of these machines translates into long-term reliability, a key advantage for businesses looking to maximize their production capabilities. The efficiency of an automatic nut bolt machine not only accelerates production but also contributes to the potential increase in profitability due to reduced labor costs and minimized material wastage.

Choosing the Right Machine

Selecting the appropriate automatic nut bolt manufacturing machine requires an understanding of specific production needs. Factors such as the type of product, volume, and the intricacy of design should guide the decision-making process. Prospective buyers can find a variety of options to suit their requirements, ensuring that they invest in a machine that aligns with their production goals.

Conclusion

In conclusion, the array of nut bolt automatic machines available caters to a wide range of industrial applications. These machines are pivotal in automating and streamlining the production of nuts and bolts, thereby enhancing the operational efficiency of businesses. With a focus on precision and durability, they represent a significant investment for manufacturers looking to optimize their production processes.